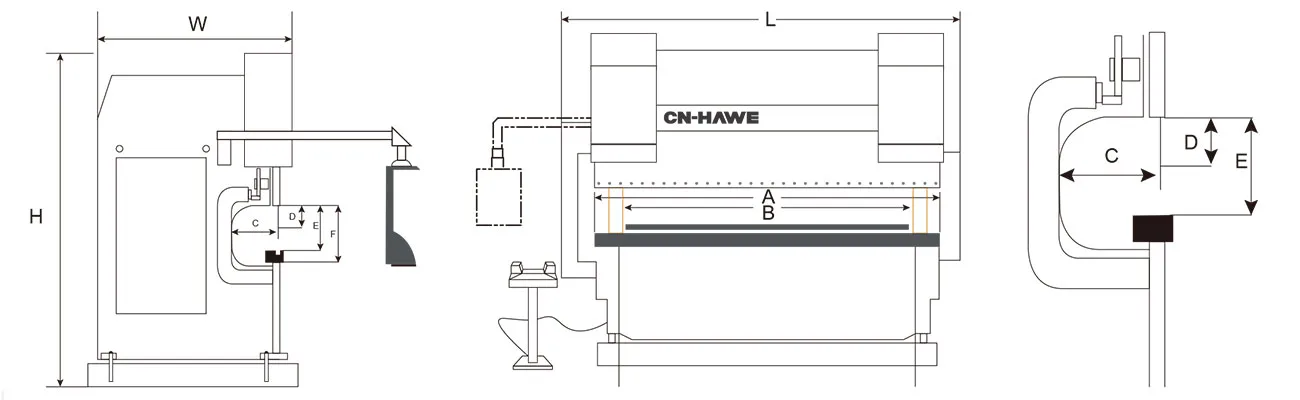

Model | Bending Force | Bending Length (A) | Oil Tank | Approaching Speed | Progress Rate | Return Speed | Column Distance (B) | Throat Depth (C) | Slider Travel (D) | Open Height (E) | Main Motor | Weight | Dimensions |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Unit | KN | mm | L | mm/s | mm/s | mm/s | mm | mm | mm | mm | KW | Ton | L*W*H (mm) |

30t/1600 | 300 | 1600 | 80 | 120 | 17 | 160 | 1300 | 200 | 80 | 320 | 5.5 | 2.3 | 1650*1200*1700 |

30t/2000 | 300 | 2000 | 100 | 140 | 17 | 160 | 1600 | 200 | 80 | 320 | 5.5 | 2.5 | 2000*1200*1700 |

40t/2500 | 400 | 2500 | 170 | 110 | 15 | 90 | 2030 | 250 | 100 | 340 | 5.5 | 3.5 | 2500*1200*1900 |

63t/2500 | 630 | 2500 | 170 | 100 | 10 | 70 | 2050 | 250 | 120 | 340 | 5.5 | 4.5 | 2500*1350*2100 |

63t/3200 | 630 | 3200 | 170 | 120 | 10 | 70 | 2510 | 250 | 120 | 340 | 5.5 | 5 | 3200*1350*2100 |

80t/2500 | 800 | 2500 | 170 | 110 | 10 | 80 | 2050 | 250 | 120 | 350 | 5.5 | 6 | 2500*1400*2150 |

80t/3200 | 800 | 3200 | 170 | 130 | 10 | 80 | 2510 | 250 | 120 | 350 | 5.5 | 6.2 | 3200*1400*2150 |

100t/2500 | 1000 | 2500 | 260 | 90 | 7.5 | 70 | 2050 | 320 | 160 | 420 | 7.5 | 6.5 | 2500*1500*2200 |

100t/3200 | 1000 | 3200 | 260 | 100 | 7.5 | 70 | 2510 | 320 | 160 | 420 | 7.5 | 7 | 3200*1500*2300 |

100t/4000 | 1000 | 4000 | 260 | 120 | 7.5 | 70 | 3100 | 320 | 160 | 420 | 7.5 | 8.5 | 4000*1750*2590 |

125t/3200 | 1250 | 3200 | 260 | 95 | 7 | 65 | 2510 | 320 | 160 | 420 | 7.5 | 7.5 | 3200*1600*2350 |

125t/4000 | 1250 | 4000 | 260 | 110 | 7 | 65 | 3100 | 320 | 160 | 420 | 7.5 | 9.5 | 4000*1600*2450 |

125t/5000 | 1250 | 5000 | 260 | 120 | 7 | 65 | 3800 | 320 | 160 | 420 | 7.5 | 9 | 5000*1600*2450 |

125t/6000 | 1250 | 6000 | 260 | 130 | 7 | 65 | 4600 | 320 | 160 | 420 | 7.5 | 11 | 6000*1600*2450 |

160t/2500 | 1600 | 2500 | 260 | 100 | 10 | 100 | 2050 | 350 | 200 | 470 | 11 | 12 | 2500*1650*2700 |

160t/3200 | 1600 | 3200 | 260 | 110 | 10 | 100 | 2510 | 350 | 200 | 470 | 11 | 14.5 | 3200*1650*2800 |

160t/4000 | 1600 | 4000 | 260 | 120 | 10 | 100 | 3100 | 350 | 200 | 470 | 11 | 19.5 | 4000*1650*2800 |

160t/5000 | 1600 | 5000 | 260 | 130 | 10 | 100 | 3800 | 350 | 200 | 470 | 11 | 13.5 | 5000*1750*3100 |

160t/6000 | 1600 | 6000 | 260 | 140 | 10 | 100 | 4600 | 350 | 200 | 470 | 11 | 11.5 | 6000*1750*3300 |

200T/3200 | 2000 | 3200 | 435 | 110 | 10 | 100 | 2510 | 350 | 200 | 470 | 15 | 15 | 3200*1650*2800 |

200T/4000 | 2000 | 4000 | 435 | 120 | 10 | 100 | 3100 | 350 | 200 | 470 | 15 | 12.5 | 4000*1650*2800 |

200T/5000 | 2000 | 5000 | 435 | 120 | 7 | 80 | 3800 | 350 | 250 | 540 | 15 | 19 | 5000*1950*3100 |

200T/6000 | 2000 | 6000 | 435 | 120 | 7 | 80 | 4600 | 350 | 250 | 540 | 15 | 21 | 6000*1950*3100 |

250T/3200 | 2500 | 3200 | 435 | 90 | 9 | 100 | 2600 | 400 | 250 | 580 | 18.5 | 17 | 3300*2100*3150 |

250T/4000 | 2500 | 4000 | 435 | 100 | 9 | 100 | 3300 | 400 | 250 | 580 | 18.5 | 20 | 4000*2100*3150 |

250T/5000 | 2500 | 5000 | 435 | 110 | 8 | 100 | 3800 | 400 | 250 | 580 | 18.5 | 23 | 5000*2100*3200 |

250T/6000 | 2500 | 6000 | 540 | 120 | 8 | 100 | 4600 | 400 | 250 | 580 | 18.5 | 25.5 | 6000*2100*3200 |

300T/3200 | 3000 | 3200 | 540 | 90 | 8 | 75 | 2600 | 400 | 250 | 580 | 18.5 | 21 | 3200*2200*3200 |

300T/4000 | 3000 | 4000 | 540 | 100 | 8 | 75 | 3100 | 400 | 250 | 580 | 18.5 | 23 | 4000*2200*3200 |

300T/5000 | 3000 | 5000 | 550 | 110 | 8 | 75 | 3800 | 400 | 250 | 580 | 18.5 | 25 | 5000*2200*3200 |

300T/6000 | 3000 | 6000 | 560 | 130 | 8 | 75 | 4600 | 400 | 250 | 580 | 18.5 | 27.5 | 6000*2200*3200 |

400T/4000 | 4000 | 4000 | 540 | 70 | 7 | 60 | 3100 | 400 | 250 | 580 | 22 | 26 | 4000*2400*3200 |

400T/5000 | 4000 | 5000 | 550 | 90 | 7 | 60 | 3800 | 400 | 250 | 580 | 22 | 32 | 5000*2400*3200 |

400T/6000 | 4000 | 6000 | 550 | 100 | 7 | 60 | 4400 | 400 | 250 | 580 | 22 | 35 | 6000*2400*3200 |

500T/4000 | 5000 | 4000 | 620 | 70 | 6 | 55 | 3100 | 500 | 320 | 620 | 30 | 33 | 4000*2650*3200 |

500T/5000 | 5000 | 5000 | 620 | 90 | 6 | 55 | 3800 | 500 | 320 | 620 | 30 | 37.5 | 5000*2650*3200 |

500T/6000 | 5000 | 6000 | 620 | 120 | 6 | 55 | 4410 | 500 | 320 | 620 | 30 | 43.5 | 6000*2700*3200 |

500T/7000 | 5000 | 7000 | 620 | 130 | 6 | 55 | 5400 | 500 | 320 | 620 | 30 | 55 | 7000*2700*3200 |

600T/4000 | 6000 | 4000 | 650 | 80 | 6 | 65 | 3100 | 500 | 320 | 620 | 37 | 45 | 4000*2700*3200 |

600T/5000 | 6000 | 5000 | 650 | 90 | 6 | 65 | 3800 | 500 | 320 | 620 | 37 | 48 | 5000*2700*3250 |

600T/6000 | 6000 | 6000 | 650 | 110 | 6 | 65 | 4600 | 500 | 320 | 620 | 37 | 55 | 6000*2700*3300 |

600T/7000 | 6000 | 7000 | 650 | 120 | 6 | 65 | 5400 | 500 | 320 | 620 | 37 | 62 | 7000*2900*3500 |