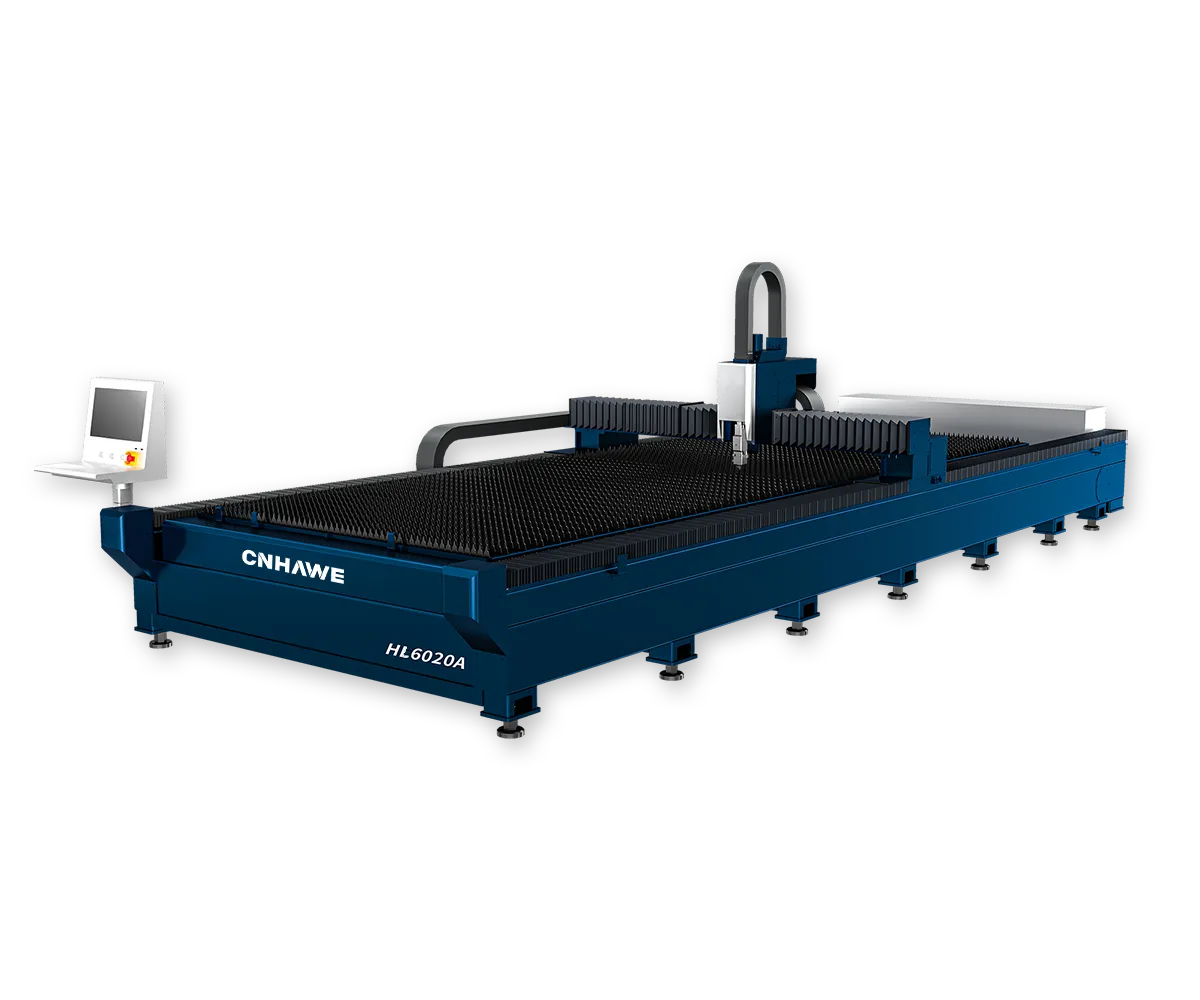

Model | HLA3015 | HLA4020 | HLA6020 |

|---|---|---|---|

Processing area | 3000mmX1500mm | 4000mmX2000mm | 6000mmX2000mm |

Power | 1500W-20000W | 1500W-20000W | 1500W-20000W |

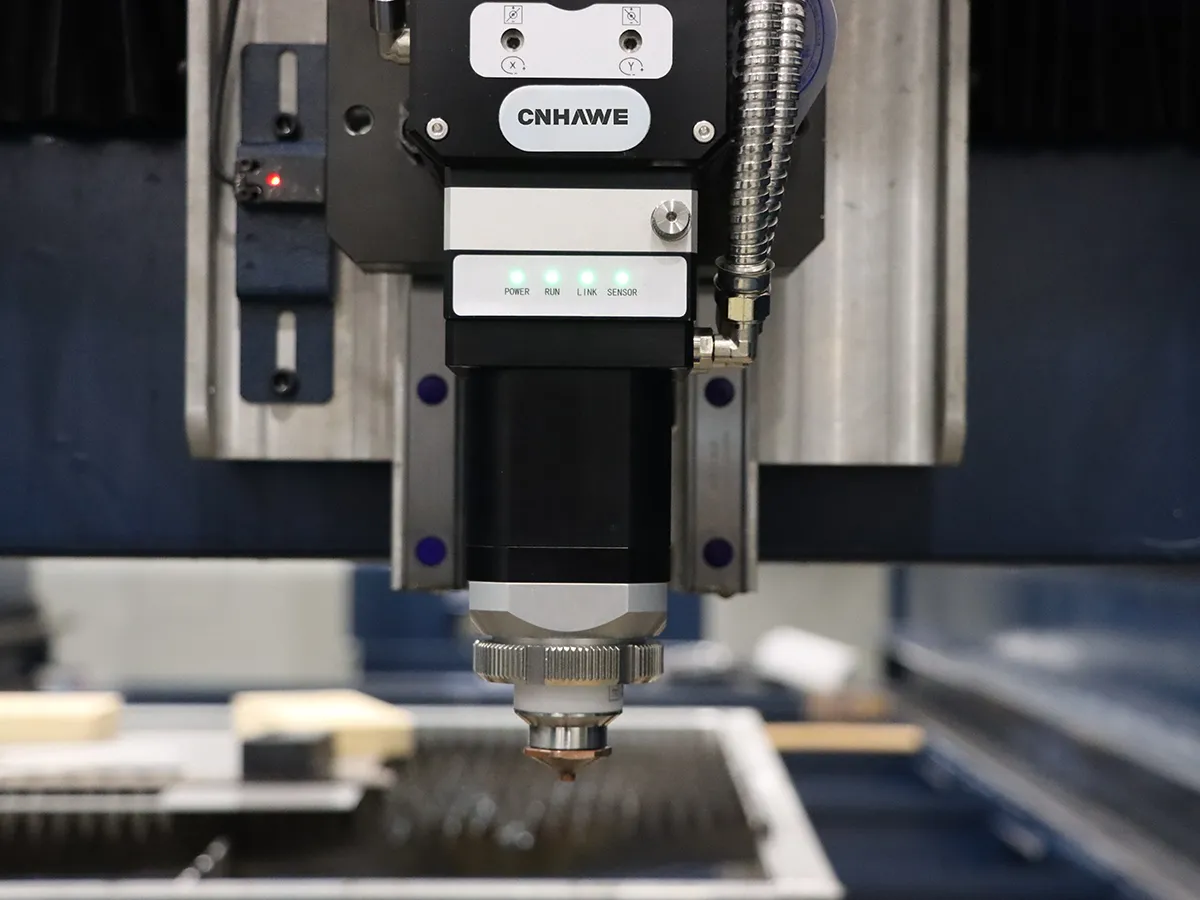

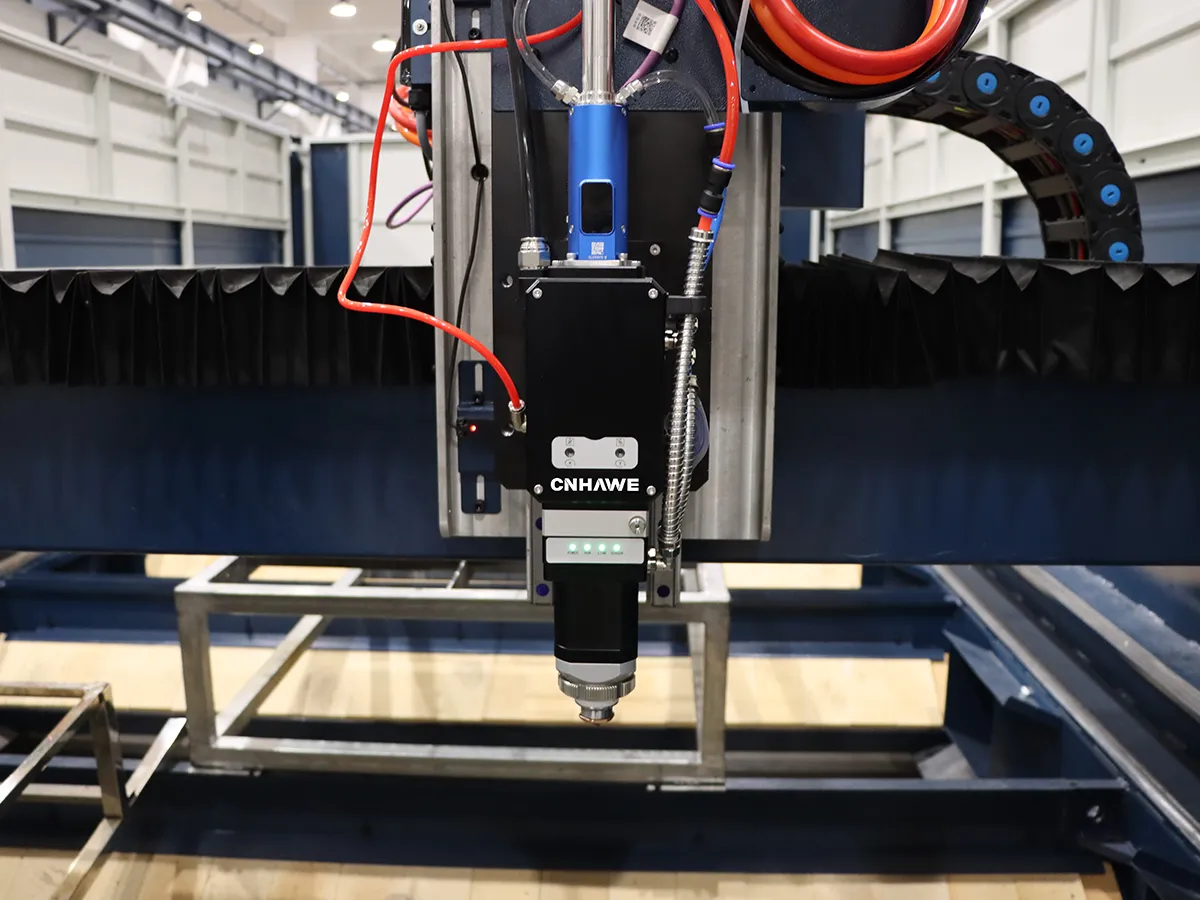

X/Y axis positioning accuracy | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

X/Y axis repeat positioning accuracy | ±0.02mm | ±0.02mm | ±0.02mm |

X/Y axis max.positioning speed | 110m/min | 110m/min | 110m/min |

X/Y axis max.acceleration | 0.8g | 0.8g | 0.8g |

Max.load of worktable | 0.9t | 1.5t | 2.8t |

Dimension(L*w) | 5000mmX2500mm | 6300mmX3000mm | 8300mmX3000mm |