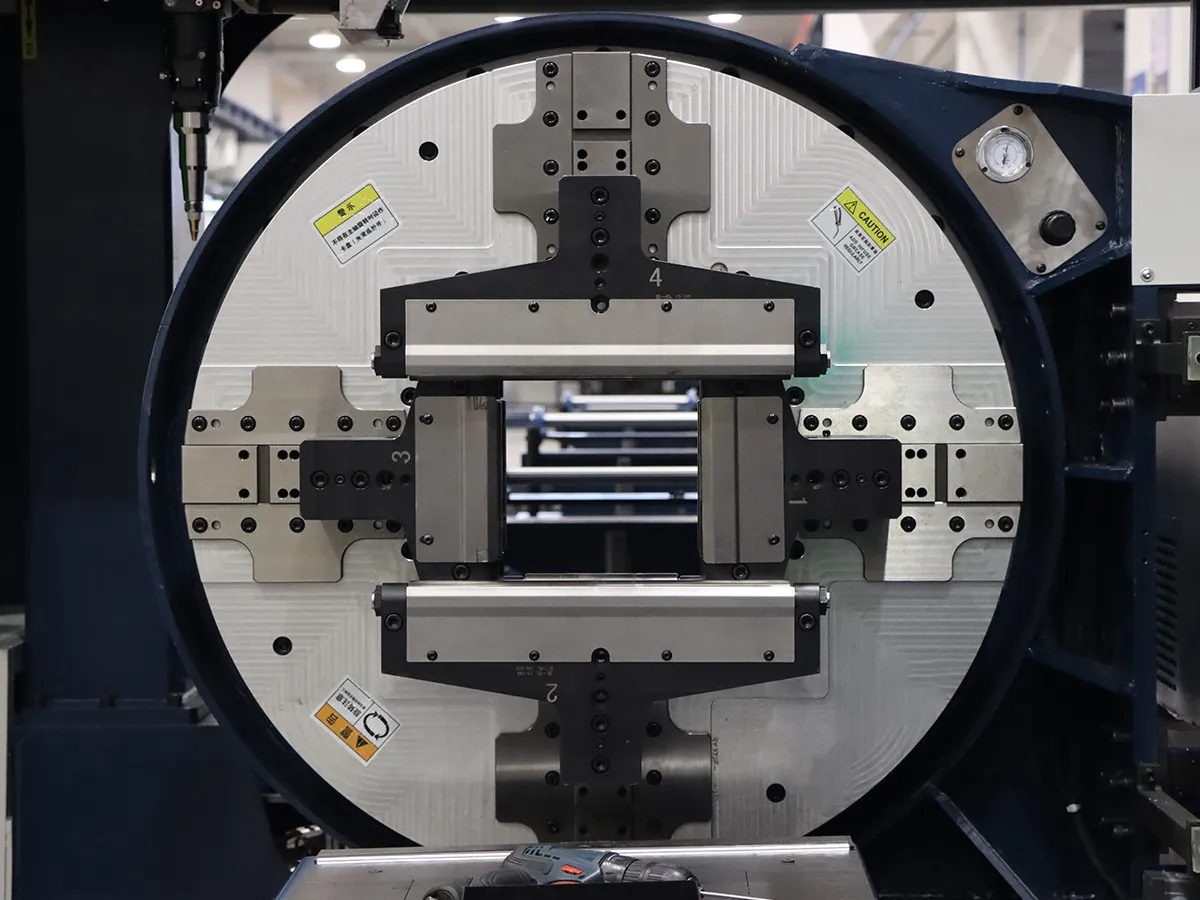

Item | Specification |

|---|---|

Pipe Dimensions | Diameter:20mm-200mm |

Length:6m/9m(320mm Optional) |

|

Tube Category | Round,Square,Oval,Rectangular,Triangle,ect. |

Laser Power | 1000W-6000W |

Max.Acceleration | 0.8G |

Rotary Speed | 80r/min |

Positioning Accuracy | ±0.05mm |

Repositioning Accuracy | ±0.05mm |

Total Weight | Over 13T |

Total Power Consumption | 18.3KVA-41KVA |

Power Supply | 380V50Hz/380V60Hz/220V60Hz |

Dimensions | 12246*5388*2355mm |