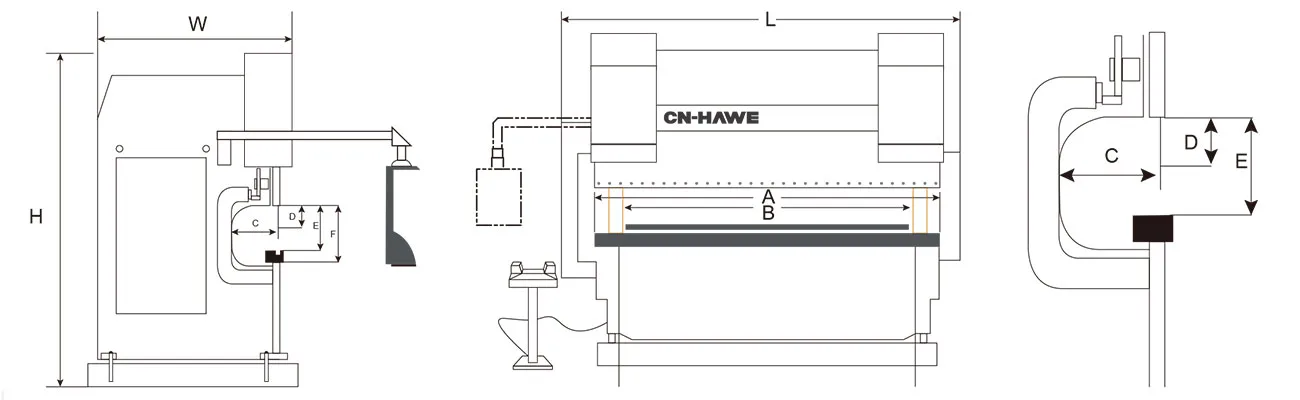

Model | Bending Force | Bending Length (A) | Oil Tank | Approaching Speed | Progress Rate | Return Speed | Column Distance (B) | Throat Depth (C) | Slider Travel (D) | Open Height (E) | Weight | Dimensions |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Unit | KN | mm | L | mm/s | mm/s | mm/s | mm | mm | mm | mm | Ton | L*W*H (mm) |

HPA-35-1250 | 350 | 1250 | 95 | 280 | 18 | 210 | 950 | 300 | 150 | 440 | 2.9 | 1480*1320*2260 |

HPA-65-1500 | 650 | 1500 | 110 | 260 | 18 | 200 | 1150 | 350 | 180 | 450 | 3.6 | 2170*1450*2360 |

HPA-65-2050 | 650 | 2050 | 160 | 260 | 18 | 200 | 1700 | 350 | 180 | 450 | 4 | 2720*1450*2360 |

HPA-65-2500 | 650 | 2500 | 200 | 260 | 18 | 200 | 2150 | 350 | 180 | 450 | 4.4 | 3170*1450*2400 |

HPA-110-2500 | 1100 | 2500 | 230 | 260 | 18 | 200 | 2000 | 410 | 220 | 490 | 6.3 | 2660*1540*2610 |

HPA-110-3100 | 1100 | 3100 | 230 | 260 | 18 | 200 | 2600 | 410 | 220 | 490 | 7.3 | 3260*1540*2610 |

HPA-110-4100 | 1100 | 4100 | 230 | 260 | 18 | 200 | 3600 | 410 | 220 | 490 | 8.7 | 4260*1540*2610 |

HPA-135-4100 | 1350 | 4100 | 230 | 260 | 18 | 200 | 3600 | 450 | 220 | 490 | 9.56 | 4260*1590*2610 |

HPA-160-3100 | 1600 | 3100 | 230 | 220 | 16 | 180 | 2600 | 410 | 220 | 490 | 8.9 | 3270*1550*2700 |

HPA-160-4100 | 1600 | 4100 | 230 | 220 | 16 | 180 | 3600 | 410 | 220 | 490 | 10.4 | 4270*1550*2700 |

HPA-220-3100 | 2200 | 3100 | 230 | 180 | 13 | 170 | 2600 | 410 | 220 | 490 | 11.2 | 3280*1830*2790 |

HPA-220-4100 | 2200 | 4100 | 230 | 180 | 13 | 170 | 3600 | 410 | 220 | 490 | 13 | 4280*1830*2790 |

HPA-220-4500 | 2200 | 4500 | 230 | 180 | 13 | 170 | 3600 | 410 | 220 | 490 | 13.5 | 4480*1830*2790 |

HPA-220-5000 | 2200 | 5000 | 230 | 180 | 13 | 170 | 4000 | 410 | 220 | 490 | 18 | 4930*2130*3350 |

HPA-220-6000 | 2200 | 6000 | 230 | 180 | 13 | 160 | 5100 | 410 | 220 | 490 | 21.6 | 5980*1920*3040 |

HPA-300-3100 | 3000 | 3100 | 230 | 170 | 11 | 140 | 2600 | 410 | 280 | 510 | 14.1 | 3290*1890*3040 |

HPA-300-4100 | 3000 | 4100 | 230 | 170 | 11 | 140 | 3600 | 410 | 280 | 510 | 16.4 | 4290*1890*3040 |

HPA-300-5000 | 3000 | 5000 | 230 | 160 | 11 | 135 | 4000 | 500 | 280 | 510 | 20.8 | 4930*2130*3350 |

HPA-300-6000 | 3000 | 6000 | 230 | 160 | 10 | 130 | 4800 | 500 | 280 | 510 | 24.5 | 5980*2130*3550 |