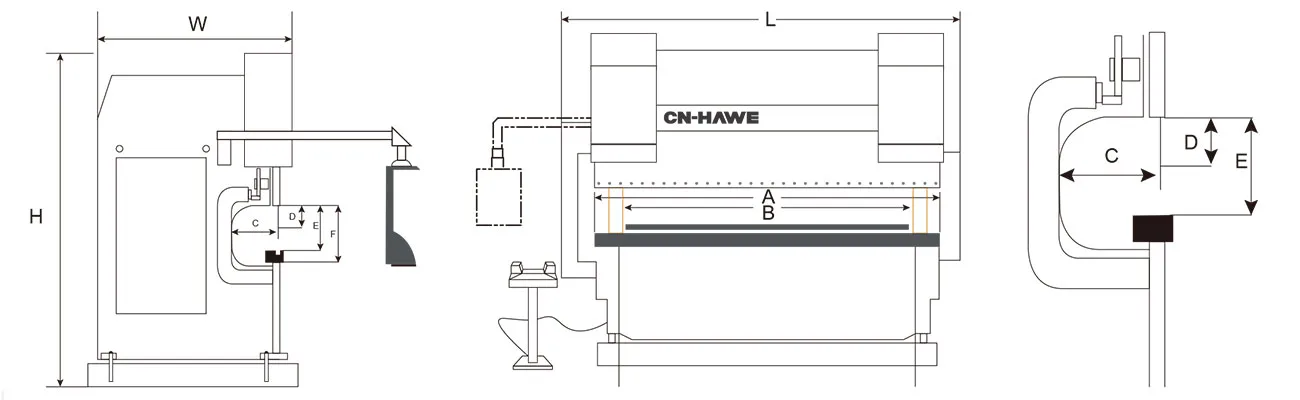

Model | Bending Force | Bending Length (A) | Oil Tank | Approaching Speed | Progress Rate | Return Speed | Column Distance (B) | Throat Depth (C) | Slider Travel (D) | Open Height (E) | Weight | Dimensions |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Unit | KN | mm | L | mm/s | mm/s | mm/s | mm | mm | mm | mm | Ton | L*W*H (mm) |

HPC-65/2500 | 650 | 2500 | 200 | 240 | 20 | 240 | 2150 | 350 | 180 | 450 | 4.14 | 2710*1400*2400 |

HPC-110/3100 | 1100 | 3100 | 230 | 220 | 14 | 180 | 2600 | 410 | 220 | 490 | 7 | 3260*1540*2610 |

HPC-110/4000 | 1100 | 4000 | 230 | 220 | 14 | 180 | 3300 | 410 | 220 | 490 | 8.1 | 4060*1540*2610 |

HPC-135/4000 | 1350 | 4000 | 230 | 220 | 14 | 180 | 3300 | 410 | 220 | 490 | 8.3 | 4060*1540*2610 |

HPC-160/3100 | 1600 | 3100 | 230 | 200 | 16 | 180 | 2600 | 410 | 220 | 490 | 8.6 | 3270*1550*2700 |

HPC-160/4000 | 1600 | 4000 | 230 | 200 | 16 | 180 | 3300 | 410 | 220 | 490 | 9.9 | 4070*1550*2700 |

HPC-250/3100 | 2500 | 3100 | 230 | 140 | 12 | 160 | 2600 | 410 | 220 | 490 | 11.24 | 3280*1930*2740 |

HPC-250/4000 | 2500 | 4000 | 230 | 140 | 12 | 160 | 3300 | 410 | 220 | 490 | 12.8 | 4080*1930*2740 |