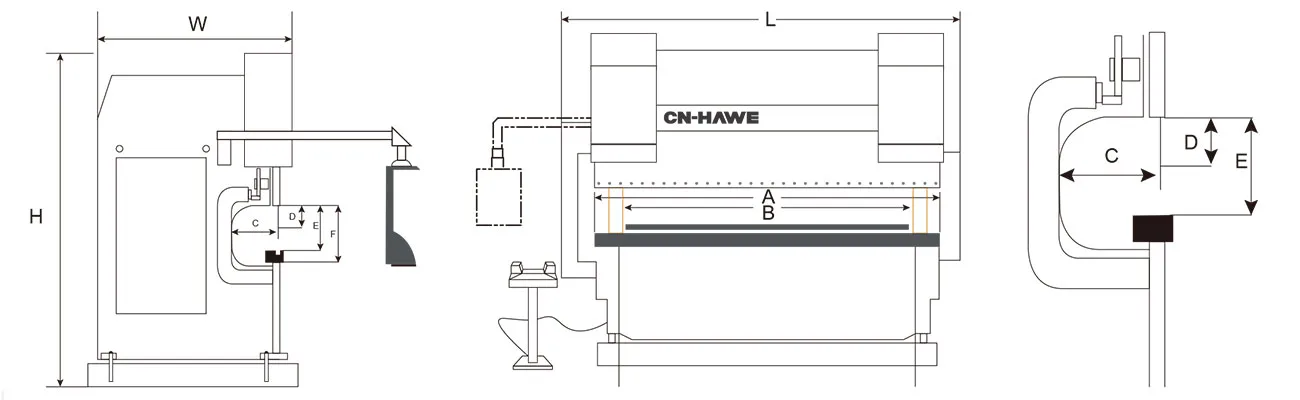

Model | Bending Force | Bending Length (A) | Oil Tank | Approaching Speed | Progress Rate | Return Speed | Column Distance (B) | Throat Depth (C) | Slider Travel (D) | Open Height (E) | Main Motor | Dimensions |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Unit | KN | mm | L | mm/s | mm/s | mm/s | mm | mm | mm | mm | KW | L*W*H (mm) |

HPE-50/1500 | 500 | 1500 | / | 230 | 25 | 230 | 1150 | 350 | 180 | 490 | 2*18KW | 1720*1500*2400 |

HPE-50/1600 | 500 | 1600 | / | 260 | 25 | 260 | 1150 | 350 | 180 | 490 | 2*7.5KW | 1820*1500*2680 |