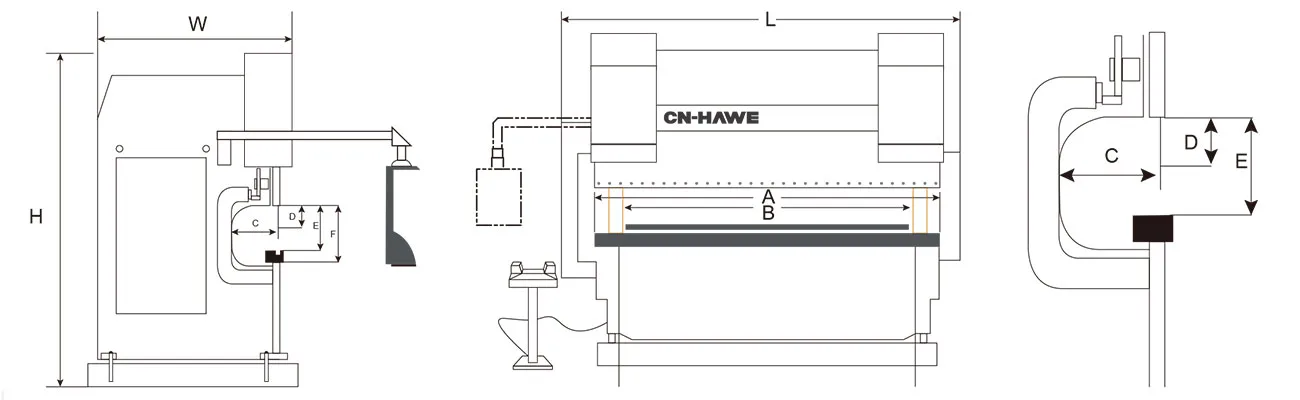

Model | Bending Force | Bending Length (A) | Oil Tank | Approaching Speed | Progress Rate | Return Speed | Column Distance (B) | Throat Depth (C) | Slider Travel (D) | Open Height (E) |

|---|---|---|---|---|---|---|---|---|---|---|

Unit | KN | mm | L | mm/s | mm/s | mm/s | mm | mm | mm | mm |

HPA-400-4000 | 4000 | 4000 | 700 | 100 | 8 | 80 | 3100 | 500 | 300 | 610 |

HPA-400-5000 | 4000 | 5000 | 700 | 100 | 8 | 80 | 3800 | 500 | 300 | 610 |

HPA-400-6000 | 4000 | 6000 | 700 | 100 | 8 | 80 | 4800 | 500 | 300 | 610 |

HPA-500-4000 | 5000 | 4000 | 800 | 100 | 8 | 80 | 3100 | 500 | 300 | 610 |

HPA-500-5000 | 5000 | 5000 | 800 | 100 | 8 | 80 | 3800 | 500 | 300 | 610 |

HPA-500-6000 | 5000 | 6000 | 800 | 100 | 8 | 80 | 5100 | 600 | 300 | 610 |

HPA-600-4000 | 6000 | 4000 | 1000 | 90 | 8 | 90 | 3100 | 600 | 320 | 650 |

HPA-600-5000 | 6000 | 5000 | 1000 | 90 | 8 | 90 | 3800 | 600 | 320 | 650 |

HPA-600-6000 | 6000 | 6000 | 1000 | 90 | 8 | 90 | 4800 | 600 | 320 | 650 |

HPA-800-6000 | 8000 | 6000 | 1800 | 90 | 8 | 90 | 4600 | 600 | 320 | 800 |

HPA-800-8000 | 8000 | 8000 | 1800 | 90 | 8 | 90 | 6600 | 600 | 320 | 800 |

HPA-1000-6000 | 10000 | 6000 | 1800 | 90 | 8 | 90 | 4600 | 600 | 400 | 900 |