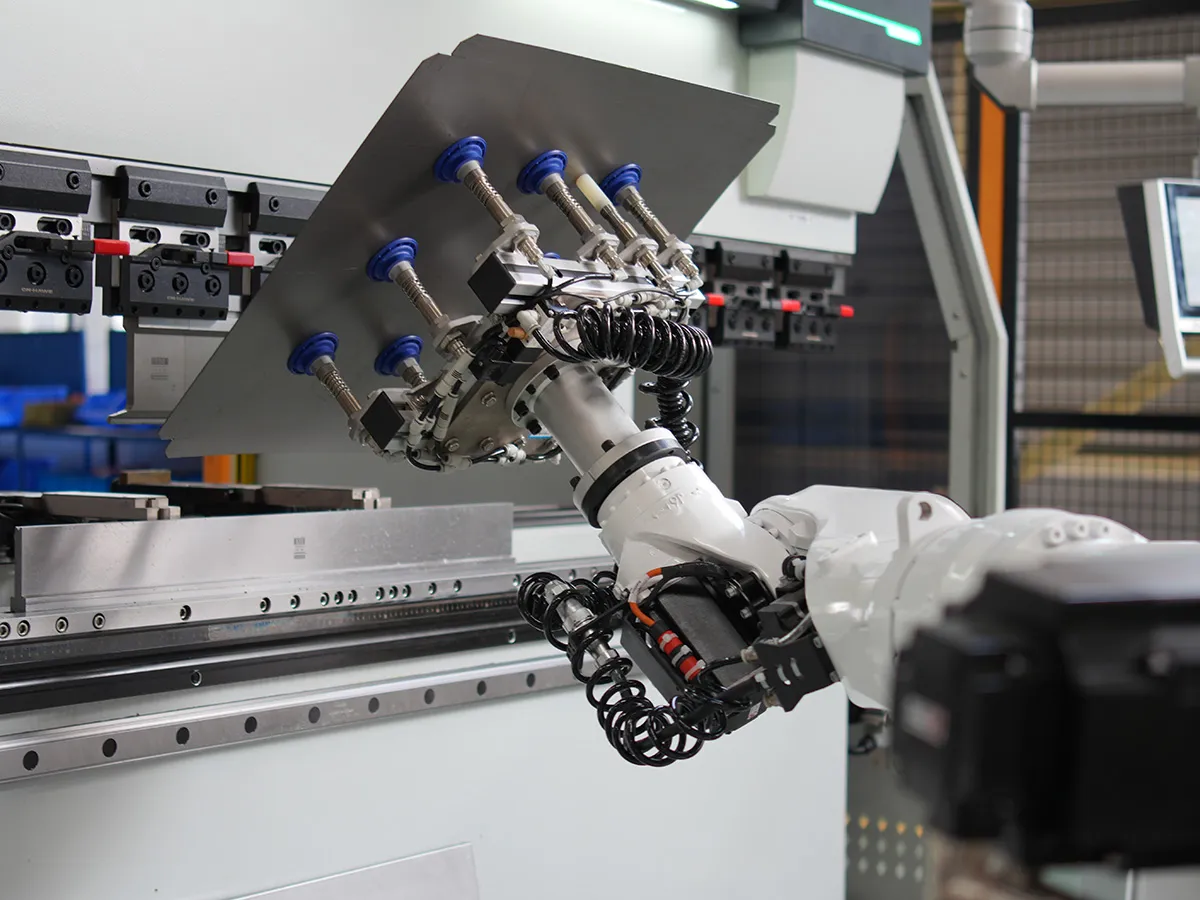

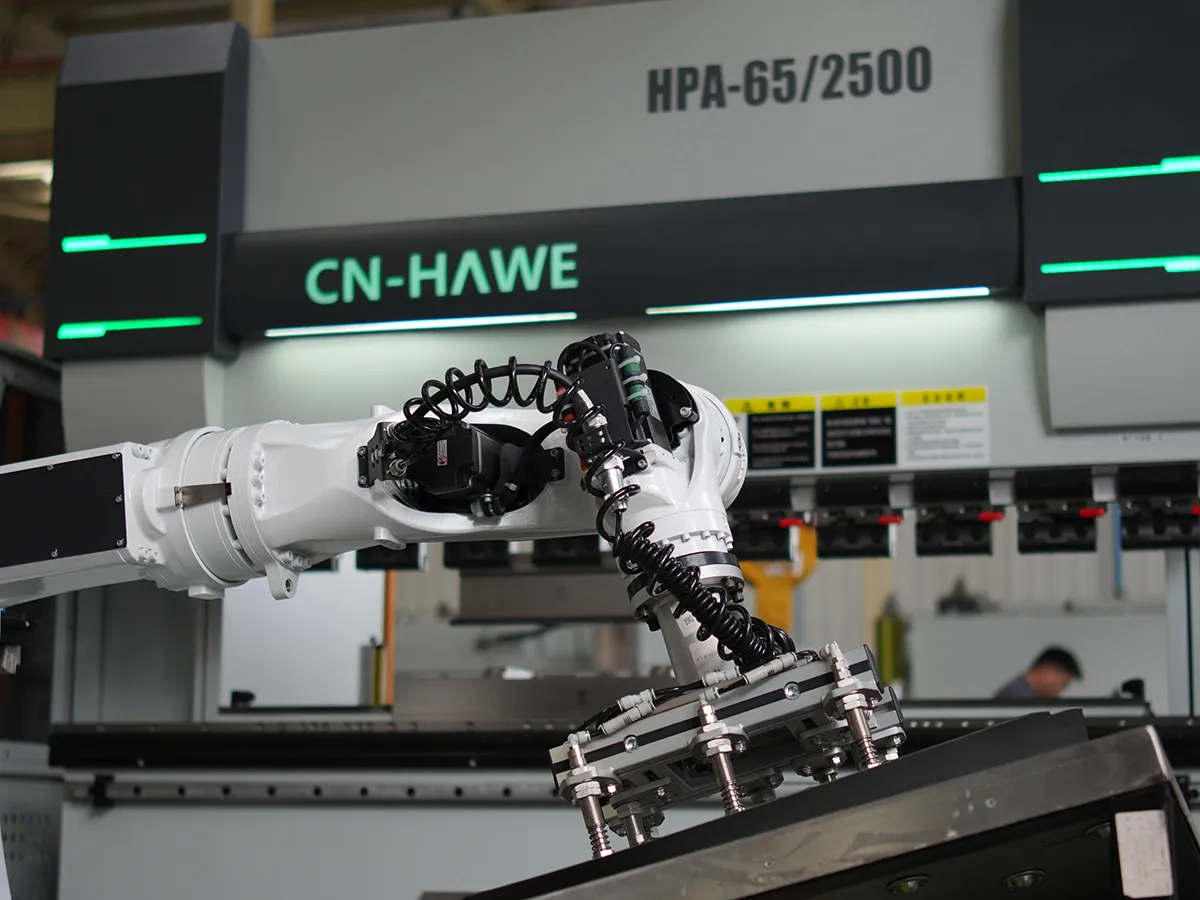

Press Brake Robotic Bending Cell

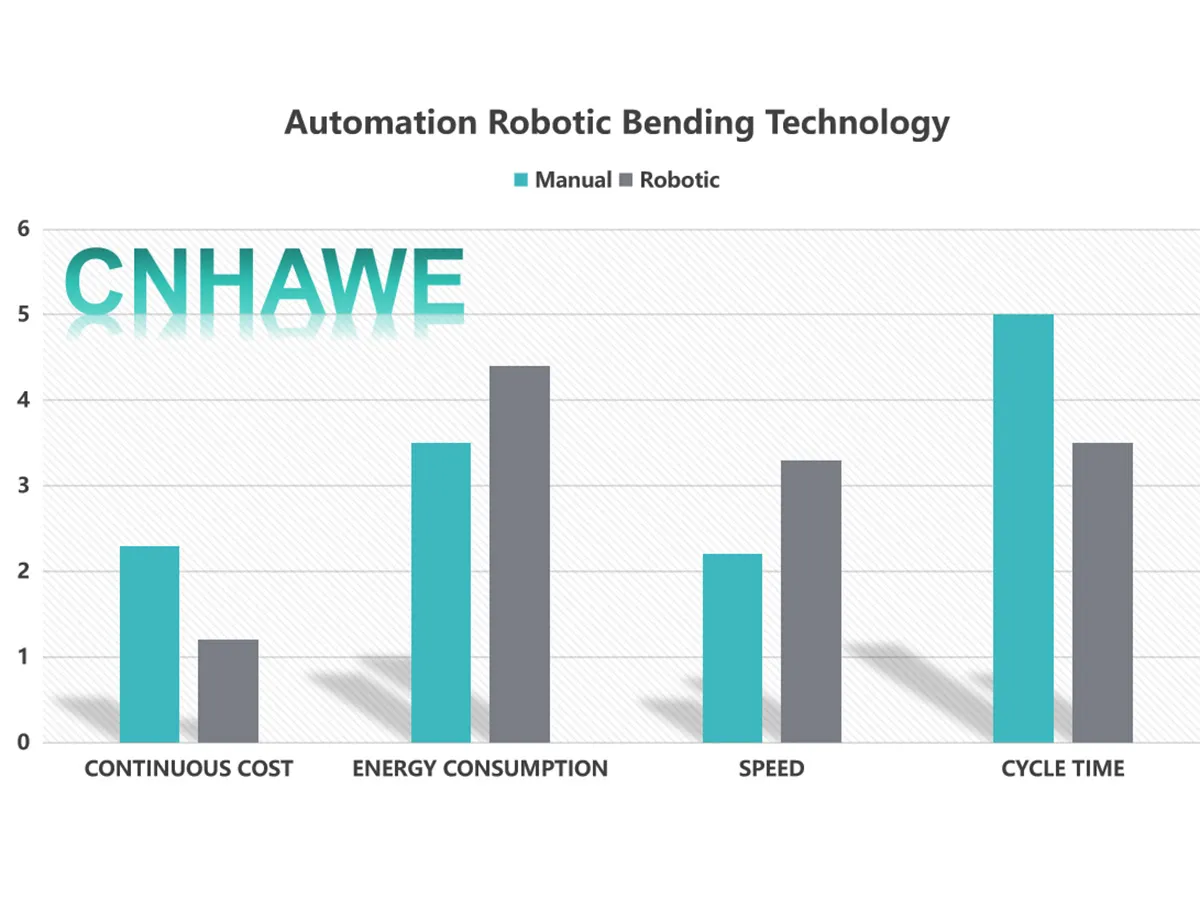

The Press Brake Robotic Bending Cell is a cutting-edge automated solution engineered to optimize the accuracy and efficiency of metal bending processes. By seamlessly integrating robotic technology with conventional press brakes, this system delivers a streamlined and highly productive workflow for bending operations. The CN-HAWE Press Brake Robotic Bending Cell marks a notable leap forward in metal forming innovation. In collaboration with several globally recognized brands, it combines robotic automation, precision, versatility, and advanced safety features, making it an ideal choice for modern manufacturing facilities aiming to enhance efficiency, improve quality, and lower operational costs. It truly unlocks productivity potential and paves the way for the transition to Industry 4.0.