2HPA Tandem CNC Press Brake

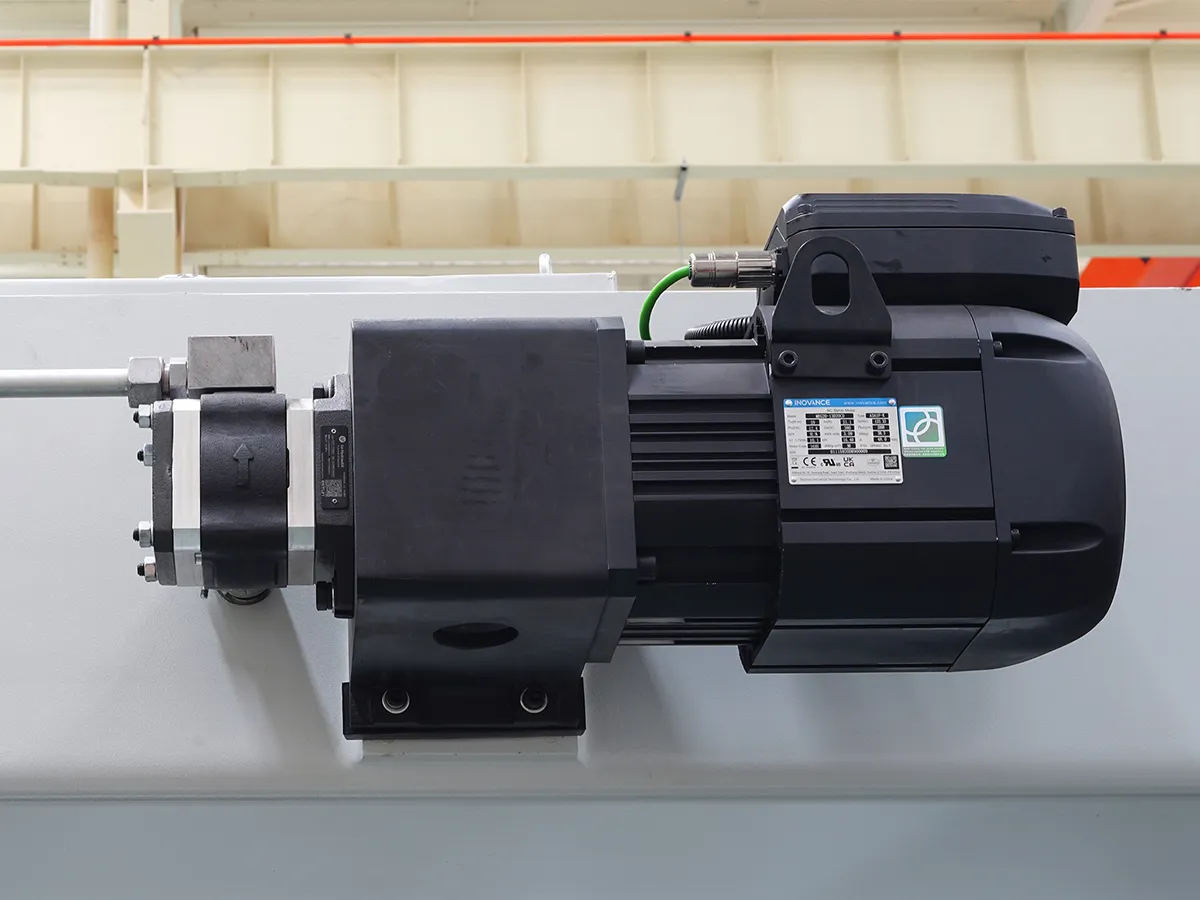

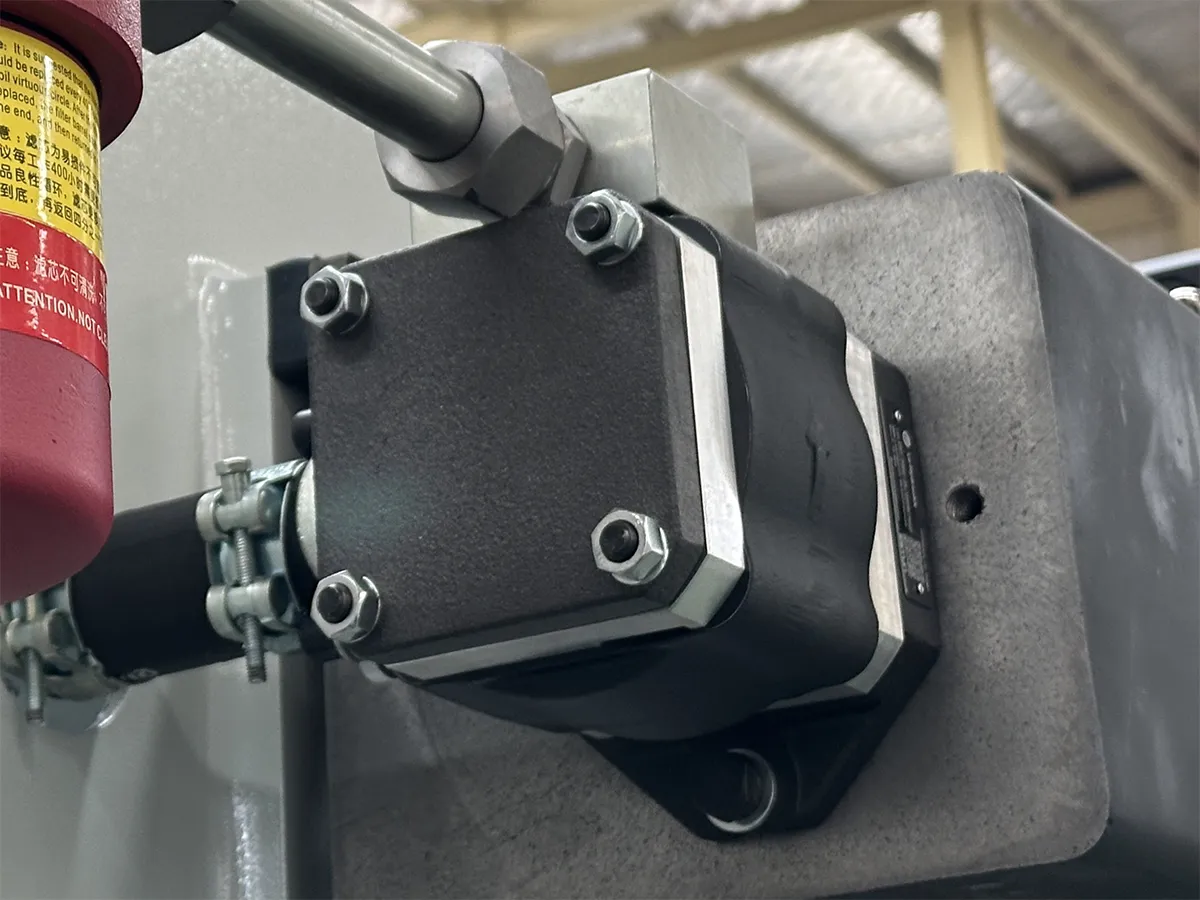

The 2HPA tandem press brake is engineered with remarkable flexibility, making it ideal for handling a diverse array of bending tasks. This machine excels in managing the bending of long workpieces, such as 12-meter light poles, with precision and ease. Furthermore, its capability to operate both independently and in tandem with other equipment enhances its adaptability, ensuring it meets various production demands and workflows seamlessly.

Beyond its hardware strengths, the 2HPA tandem series press brake offers robust software support that plays a vital role. Partnering with CN-HAWE, the controller manufacturers provide extensive application libraries and tailored development services, enabling users to fine-tune machine settings to meet specific needs. These advanced software tools assist operators in optimizing bending sequences, forecasting material rebound, and minimizing trial-and-error processes, which collectively boost efficiency and elevate product quality.

In summary, the 2HPA series press brake has emerged as a preferred choice across numerous industries, particularly in processing large metal components, thanks to its outstanding performance and flexibility. Whether utilized as a standalone machine or integrated into complex automated production lines, it delivers efficient, precise, and dependable solutions.